Introduction to HLS series new vertical roller press sand machine:

The new vertical roller press sand machine produced by Phoenix uses the grinding roller layer pressing powder principle of the vertical mill for crushing, and applies it to the sand making equipment for the production of machine-made sand. It has been widely used in sand making production lines worldwide. Its high production efficiency, low unit energy consumption, good product particle shape, micro negative pressure operation, low dust, especially the long service life of vulnerable parts such as pressure rollers and pressure plate liners, have won high praise from users. The development and application of a new type of vertical roller press sand machine will have a significant impact on the mechanism sand industry. Bringing good news to mechanism sand enterprises in terms of increasing production capacity, reducing energy consumption (cost), and creating economic benefits.

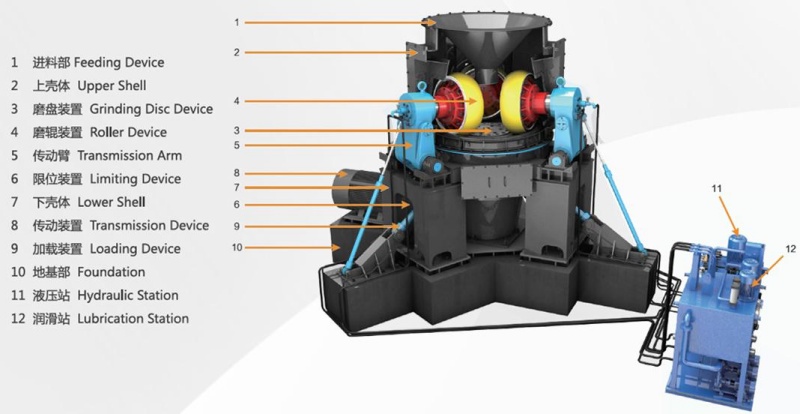

Effect diagram of new vertical roller press sand machine

Working principle of HLS series new vertical roller press sand machine:

Driven by an electric motor, the reducer drives the pressure plate to rotate;

The stone that needs to be crushed is fed into the center of the rotating pressure plate through the feeding port;

Under the action of centrifugal force, the material moves towards the periphery of the pressure plate and enters the pressure plate roller conveyor;

Under the pressure of the roller, the material is crushed by rolling, grinding, and shearing;

The crushed material moves towards the edge of the pressure plate under the action of centrifugal force and falls into the chamber of the lower shell;

Scrape the finished sand to the discharge port through the scraper plate connected to the lower part of the pressure plate;

After screening, the unqualified particles are transported back by the conveying equipment and mixed with newly fed materials to be re rolled and crushed. This cycle completes the entire process of roller pressing sand operation.

Main component structure of vertical roller press sand machine

Performance advantages of the HLS series new vertical roller press sand machine:

1. High production efficiency and a nearly 40% reduction in unit energy consumption;

2. Can adapt to any strength of raw materials and adjust the fineness modulus of sand according to user needs;

3. Good particle size distribution and shape of sand;

4. Long lifespan of vulnerable parts, high equipment operation rate, and low maintenance costs;

5. The equipment has intelligent and environmentally friendly features, and is easy to maintain and repair.

Technical parameters of HLS series new vertical roller press sand machine:

| Model | HLS800 | HLS1400 | HLS1700 | HLS1900 | HLS2200 |

| Grinding disc diameter(mm) | 800 | 1400 | 1700 | 1900 | 2200 |

| Grinding roller diameter(mm) | 650 | 1100 | 1400 | 1500 | 1500 |

| Number of grinding rollers (pieces) | 3 | 3 | 3 | 3 | 3 |

| Material properties | Limestone, granite, etc | ||||

| Feed particle size(mm) | <25mm | ||||

| production(t/h) | 40 | 150 | 260 | 320 | 380 |

| Fineness modulus | 1.6~3.1 | ||||

| power | 110kW | 315kW | 450kW | 630kW | 710kW |

Introduction to the main components of the HLS series new vertical roller press sand machine:

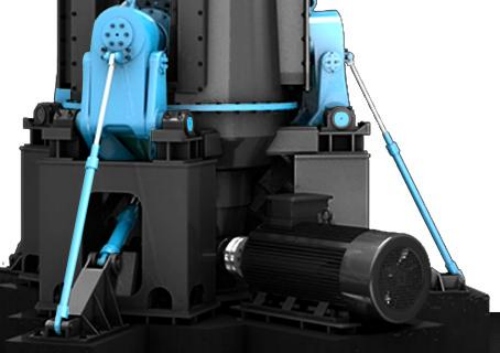

1. Transmission device: The transmission device consists of three parts: the main motor, the coupling, and the reducer. It is installed below the pressure plate and not only drives the pressure plate to rotate, but also bears the weight and the roller pressure applied by the pressure device. It is one of the most important components in the roller press sand machine.

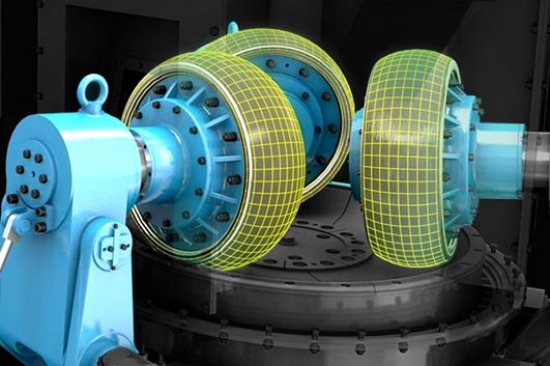

2. Roller press device: The roller press device mainly consists of a pressure plate and a pressure roller, and is an important crushing component of the roller press sand machine. We use disc-shaped pressure plates and tire shaped pressure rollers, both of which are equipped with replaceable lining plates and roller sleeves. We also use high chromium alloy and wear-resistant welding materials, with a hardness of HRC60 ± 3 and a service life of up to 3000 hours.

3. Pressure device: It adopts a hydraulic automatic control system to apply and control its force on the material, and can adjust the pressure according to the changes in the material's grindability. At the same time, it is equipped with an energy storage device that acts as a buffer. When encountering large and hard debris, the pressure roller can jump up to prevent damage to broken components and transmission devices due to overload.

4. Limit device: The unique limit device allows the equipment to start under light load, and the gap between the pressure roller and the pressure plate can be adjusted. It can ensure a stable thickness of the material layer, improve crushing efficiency, and also prevent direct contact between the pressure roller and the pressure plate in case of abnormal situations such as material breakage, providing protection for the equipment.

Support and Service:

Phoenix Mining Equipment (Shanghai) Co., Ltd. is a joint venture between Jiangsu Phoenix Machinery Co., Ltd. and Blackstone Technology Co., Ltd. It is a high-tech joint-stock enterprise that integrates research and development, manufacturing, sales, installation and commissioning of various crushing and screening equipment, complete sets of manual sand making equipment, and complete sets of industrial grinding equipment. The company is committed to building a well-known brand of intelligent crushing and screening equipment in China. We welcome experts and colleagues to guide our work and achieve win-win cooperation!

Service Hotline:+86-21-33781259

E-mail:info@shpks.com

company address:No. 15, Lane 15, Gudan Road, Pudong New Area, Shanghai

Phoenix Mining Equipment (Shanghai) Co., Ltd. is a Sino-US joint venture that produces and sells various types of crushing equipment, sand making equipment, milling equipment, crushing and screening equipment and other complete sets of sand and ore production line equipment. "Science and Technology Co., Ltd." and "Jiangsu Phoenix Machinery Co., Ltd···